Because operating rooms are high-stakes environments, precision and reliability are not just desires, they are prerequisites. A well-planned network is set behind every successful surgery, and at the center of this network are Surgical Instruments Manufacturers such as D.R. Surgicare. They actively contribute to the healthcare ecosystem with devices that surgeons trust to perform life-saving procedures. Availability for everything from routine general operations to extremely specialized maneuvers is directly determined by the capability of surgical instruments to impact surgical outcomes; therefore, expertise in surgical instrument making becomes indispensable.

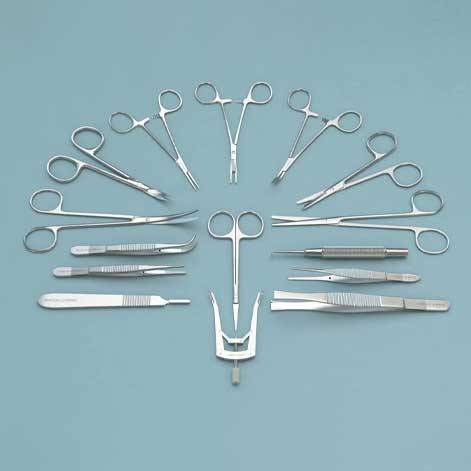

Every type of modern surgery today has particular demands. Today, hospitals perform multiple types of procedures, each requiring its range of specific instruments tailored to be functionally specific. Ergonomic design, rust resistance, the capability of sterilization, and extreme conditions are among the best qualities sought for these instruments. Forceps, scalpels, clamps, scissors, and retractors are only a few components that go into achieving extraordinarily tight tolerances in manufacture. Manufacturers aren't mere suppliers to hospitals; they partner with them in delivering healthcare, silently yet strongly contributing to the safety and success of critical operations. Such detailed attention has ensured that the surgeon can focus completely on the patient, knowing that tools will not fail.

The last several years have seen a tremendous uptick in minimally invasive surgical approaches, and therefore, a corresponding increase in the need for tools with the highest precision. This is where they become critical, indeed, with Laparoscopy Instruments Manufacturers. Performing laparoscopic surgeries requires having instruments that can work through very small incisions with maximum control in the surgeon's hands. Trocars, graspers, dissectors, and laparoscopes are instruments that need high-end engineering and micro-manufacturing processes. Hospitals want instruments for laparoscopy that are less traumatic to tissues, enable shorter recovery times, and follow the current trends for continuing all surgeries, especially outpatient surgery. Such a level of surgical excellence can be supported by manufacturers that commit themselves to consistently providing impeccable, lightweight, and sterilizable instruments.

Requires surgical devices to meet stringent regulatory stipulations regarding patient safety, most particularly in critical care and trauma cases where the surgeries demand speed as well as complexity. Manufacturers committed extensive resources toward R&D to stay ahead in meeting the evolving medical needs. This includes engaging ideas from surgeons and experimenting with fresh materials, for example, high-grade stainless steel and titanium, and availing the latest sophisticated finishing techniques to eradicate even microscopic imperfections. Hospitals lean on this innovation as a justification to modernize their equipment as regards those healthcare protocols. More new methods and technologies create the need for hospitals and manufacturers to converge even more.

Another major area in hospital surgery departments is women's health, in which trade involves most of the work done by Gynaecology Instruments Manufacturers. Hysterectomies, as part of gynaecological surgeries, along with diagnostic procedures like colposcopies and biopsies, require highly specialized instruments made just right for accuracy, safety, and comfort. Speculums, uterine dilators, curettes, and forceps are used in these surgeries that compose both routine-based-as well as complex-based interventions. It is through this type of instrumentation that manufacturing companies add to their great contribution toward the advancement of women's healthcare. Their innovative designs ensure safer procedures with reduced recovery times and improved accuracy in diagnosis, which is key to hospital efficiency and patient trust.

Surgical equipment makers are, furthermore, beyond just background players in the greater arena called medicine. These are crucial coactors molding futures in surgical care. Pushing the envelope of technology ever farther and complying with the strictest health standards while understanding the specific needs of the different medical specialties are what make it happen for hospitals with faster, safer, and more effective surgical results. Their contributions remain firmly rooted in every operating table, every incision, and every life saved as healthcare progresses.